ENERGY EFFICIENT MOTORS IN PUMPING SYSTEMS

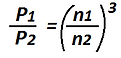

Typical high efficiency motor curves (150 kW, 4-Pole)

New High Efficiency motors have a very flat efficiency curve all the way down to 25-30% of full load. Pumps usually have power requirements in the area where the motor efficiency curve is flat. Therefore the motor is generally not a cause for concern in pumping systems, unless it is very much oversized.

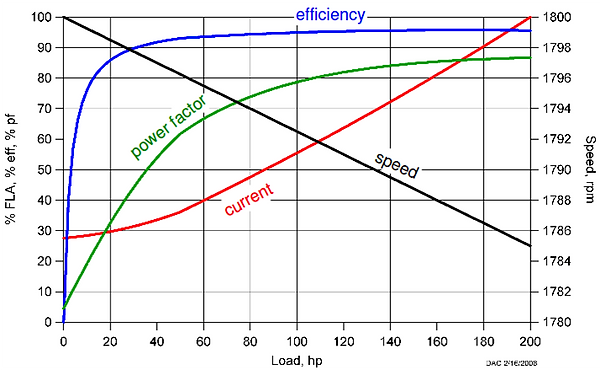

It is worth noting that there may be a few percentage points of efficiency that can be gained if the motor in service is very old or degraded. It will almost never be cost effective to simply replace a standard efficiency motor with a premium efficiency motor, however (as long as the existing motor is functional).

Motor improvements

- Determine existing condition of motors

- Electrical measurements

- Motor circuit analysis, infrared thermography

- Efficiency

- Plan ahead for repair/replace options

- Use MotorMaster software to evaluate savings by upgrading to a premium efficiency motor

- Application of variable speed drive will impact new motor type

- Evaluate how pump upgrades may effect the motor

- Opportunity to resize the motor

- Effect of variable speed drive

- Impact on motor service factor

- Determine how motor upgrades will impact pump performance

Whether the replacing of an energy efficient motor can reduce energy consumption in a pumping system?

This question can sound strange but sometimes it can happen.

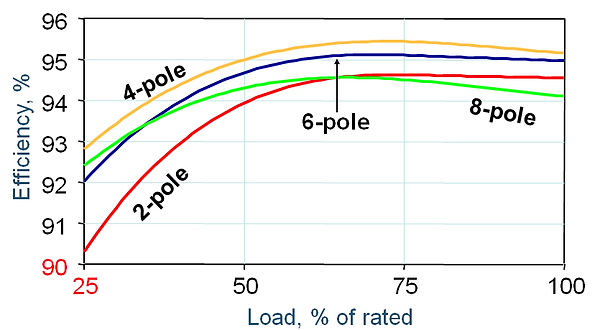

High-efficiency motors have less slip and more speed of rotation. In accordance with affinity laws

- The Higher rpm of premium efficiency motors will increase pump capacity and power.

- The absorbed power is roughly proportional to the cube of the speed!!! A 2% speed increase could lead to 8% higher power usage